Alanında Uzman Ekip

Profesyonel mühendis kadromuz, talebinize yönelik teknik destek sunarak doğru ürünü sunmayı hedefler.

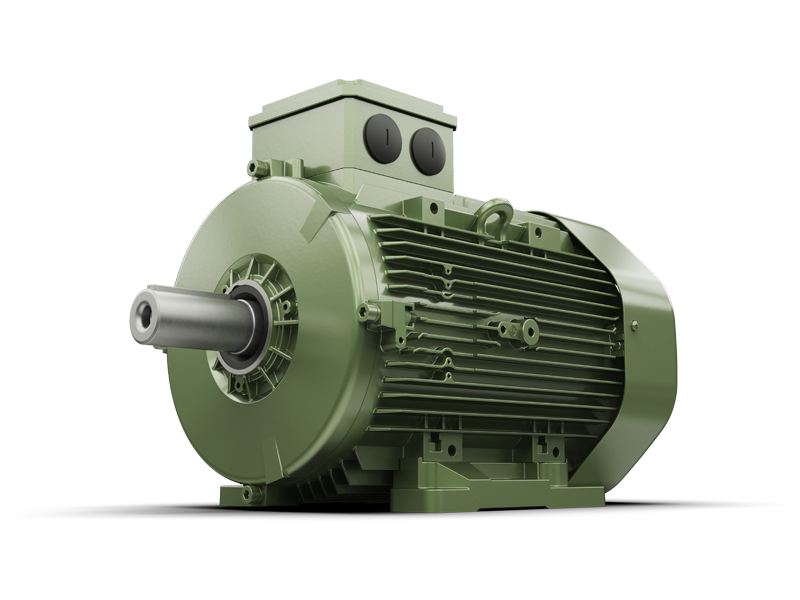

Yüksek Kalite, Kesin Güven: Merkez Motor

Kuruluşundan beri süregelen müşteri odaklı hizmet anlayışı ve profesyonel bakış açısı ile bugün Türkiye’nin en büyük elektrik motoru ve redüktör tedarikçilerinden biri olmayı başarmıştır. 28 yılı aşkın tecrübesi, uzman kadrosu ve mühendis ekibi ile sektörün taleplerini en hızlı ve en doğru biçimde karşılayabilecek donanımdadır.

Merkez Motor olarak İstanbul’un Avrupa Yakası ve Anadolu Yakası’nda bulunan ofis – depo alanlarımız ile Türkiye’nin dört bir yanına ve 3 kıtada 30’dan fazla ülkeye stoktan kesintisiz hizmet sağlamaktayız.

Profesyonel mühendis kadromuz, talebinize yönelik teknik destek sunarak doğru ürünü sunmayı hedefler.

Uzman ekibimiz, tüm ürünlerimiz için bakım onarım talebinize en hızlı ve etkili çözümleri sunarak, iş sürekliliğinizi ve verimliliğinizi maksimize etmeyi hedefler.

Merkez Motor olarak her türlü talebiniz ile hassasiyet ile ilgilenmekteyiz dolayısıyla "Yüksek Müşteri Memnuniyeti" en büyük önceliğimizdir.

Kişisel verileriniz; veri sorumlusu olarak Firma Adı (“Merkez Motor” olarak adlandırılacaktır.) tarafından işletilen (www.merkezmotor.com.tr) internet sitesini ziyaret edenlerin gizliliğini korumak Kurumumuzun önde gelen ilkelerindendir. Bu Çerez Kullanımı Politikası (“KVKK”), tüm web sitesi ziyaretçilerimize ve kullanıcılarımıza hangi tür çerezlerin hangi koşullarda kullanıldığını açıklamaktadır.

Çerezler, bilgisayarınız ya da mobil cihazınız üzerinden ziyaret ettiğiniz internet siteleri tarafından cihazınıza veya ağ sunucusuna depolanan küçük metin dosyalarıdır.

Genellikle ziyaret ettiğiniz internet sitesini kullanmanız sırasında size kişiselleştirilmiş bir deneyim sunmak, sunulan hizmetleri geliştirmek ve deneyiminizi iyileştirmek için kullanılır ve bir internet sitesinde gezinirken kullanım kolaylığına katkıda bulunabilir. Çerez kullanılmasını tercih etmezseniz tarayıcınızın ayarlarından Çerezleri silebilir ya da engelleyebilirsiniz. Ancak bunun internet sitemizi kullanımınızı etkileyebileceğini hatırlatmak isteriz. Tarayıcınızdan Çerez ayarlarınızı değiştirmediğiniz sürece bu sitede çerez kullanımını kabul ettiğinizi varsayacağız.

İnternet sitelerinde yer alan çerezlerde, türüne bağlı olarak, siteyi ziyaret ettiğiniz cihazdaki tarama ve kullanım tercihlerinize ilişkin veriler toplanmaktadır. Bu veriler, eriştiğiniz sayfalar, incelediğiniz hizmet ve ürünler, tercih ettiğiniz dil seçeneği ve diğer tercihlerinize dair bilgileri kapsamaktadır.

Çerezler, ziyaret ettiğiniz internet siteleri tarafından tarayıcılar aracılığıyla cihazınıza veya ağ sunucusuna depolanan küçük metin dosyalarıdır. Sitede tercih ettiğiniz dil ve diğer ayarları içeren bu küçük metin dosyaları, siteye bir sonraki ziyaretinizde tercihlerinizin hatırlanmasına ve sitedeki deneyiminizi iyileştirmek için hizmetlerimizde geliştirmeler yapmamıza yardımcı olur. Böylece bir sonraki ziyaretinizde daha iyi ve kişiselleştirilmiş bir kullanım deneyimi yaşayabilirsiniz.

İnternet Sitemizde çerez kullanılmasının başlıca amaçları aşağıda sıralanmaktadır:

Oturum çerezlerini ziyaretinizi süresince internet sitesinin düzgün bir şekilde çalışmasının teminini sağlamaktadır. Sitelerimizin ve sizin, ziyaretinizde güvenliğini, sürekliliğini sağlamak gibi amaçlarla kullanılırlar. Oturum çerezleri geçici çerezlerdir, siz tarayıcınızı kapatıp sitemize tekrar geldiğinizde silinir, kalıcı değillerdir.

Bu tür çerezler tercihlerinizi hatırlamak için kullanılır ve tarayıcılar vasıtasıyla cihazınızda depolanır Kalıcı çerezler, sitemizi ziyaret ettiğiniz tarayıcınızı kapattıktan veya bilgisayarınızı yeniden başlattıktan sonra bile saklı kalır. Tarayıcınızın ayarlarından silinene kadar bu çerezler tarayıcınızın alt klasörlerinde tutulurlar.

Kalıcı çerezlerin bazı türleri; İnternet Sitesini kullanım amacınız gibi hususlar göz önünde bulundurarak sizlere özel öneriler sunulması için kullanılabilmektedir.

Kalıcı çerezler sayesinde İnternet Sitemizi aynı cihazla tekrardan ziyaret etmeniz durumunda, cihazınızda İnternet Sitemiz tarafından oluşturulmuş bir çerez olup olmadığı kontrol edilir ve var ise, sizin siteyi daha önce ziyaret ettiğiniz anlaşılır ve size iletilecek içerik bu doğrultuda belirlenir ve böylelikle sizlere daha iyi bir hizmet sunulur.

Ziyaret ettiğiniz internet sitesinin düzgün şekilde çalışabilmesi için zorunlu çerezlerdir. Bu tür çerezlerin amacı, sitenin çalışmasını sağlamak yoluyla gerekli hizmet sunmaktır. Örneğin, internet sitesinin güvenli bölümlerine erişmeye, özelliklerini kullanabilmeye, üzerinde gezinti yapabilmeye olanak verir.

İnternet sitesinin kullanım şekli, ziyaret sıklığı ve sayısı, hakkında bilgi toplayan ve ziyaretçilerin siteye nasıl geçtiğini gösterirler. Bu tür çerezlerin kullanım amacı, sitenin işleyiş biçimini iyileştirerek performans arttırmak ve genel eğilim yönünü belirlemektir. Ziyaretçi kimliklerinin tespitini sağlayabilecek verileri içermezler. Örneğin, gösterilen hata mesajı sayısı veya en çok ziyaret edilen sayfaları gösterirler.

Ziyaretçinin site içerisinde yaptığı seçimleri kaydederek bir sonraki ziyarette hatırlar. Bu tür çerezlerin amacı ziyaretçilere kullanım kolaylığı sağlamaktır. Örneğin, site kullanıcısının ziyaret ettiği her bir sayfada kullanıcı şifresini tekrar girmesini önler.

Ziyaretçilere sunulan reklamların etkinliğinin ölçülmesi ve reklamların kaç kere görüntülendiğinin hesaplanmasını sağlarlar. Bu tür çerezlerin amacı, ziyaretçilerin ilgi alanlarına özelleştirilmiş reklamların sunulmasıdır.

Aynı şekilde, ziyaretçilerin gezinmelerine özel olarak ilgi alanlarının tespit edilmesini ve uygun içeriklerin sunulmasını sağlarlar. Örneğin, ziyaretçiye gösterilen reklamın kısa süre içinde tekrar gösterilmesini engeller.

Çerezlerin kullanımına ilişkin tercihlerinizi değiştirmek ya da çerezleri engellemek veya silmek için tarayıcınızın ayarlarını değiştirmeniz yeterlidir.

Birçok tarayıcı çerezleri kontrol edebilmeniz için size çerezleri kabul etme veya reddetme, yalnızca belirli türdeki çerezleri kabul etme ya da bir internet sitesinin cihazınıza çerez depolamayı talep ettiğinde tarayıcı tarafından uyarılma seçeneği sunar.

Aynı zamanda, daha önce tarayıcınıza kaydedilmiş çerezlerin silinmesi de mümkündür.

Çerezleri devre dışı bırakır veya reddederseniz, bazı tercihleri manuel olarak ayarlamanız gerekebilir, hesabınızı tanıyamayacağımız ve ilişkilendiremeyeceğimiz için internet sitesindeki bazı özellikler ve hizmetler düzgün çalışmayabilir. Tarayıcınızın ayarlarını aşağıdaki tablodan ilgili link’e tıklayarak değiştirebilirsiniz.

İnternet Sitesi Gizlilik Politikası …./…./…. .tarihlidir. Politika’nın tümünün veya belirli maddelerinin yenilenmesi durumunda Politika’nın yürürlük tarihi güncellenecektir. Gizlilik Politikası Kurum’un internet sitesinde (www.merkezmotor.com.tr) yayımlanır ve kişisel veri sahiplerinin talebi üzerine ilgili kişilerin erişimine sunulur.

Merkez Motor

Adres: Terazidere Mah. Pak Sk. No: 11/A 34035 Bayrampaşa / İstanbul

Telefon: 444 33 31 | +90 (212) 674 85 16

E – Posta: info@merkezmotor.com.tr

Web Adresi: www.merkezmotor.com.tr